the best choice in the production field.

ORCA-20

the best choice in the production field.

ORCA-40

of refrigerators and air conditioners.

ORCA-SEALER

manufacturing to replace traditional methods.

ORCA-SPLICER

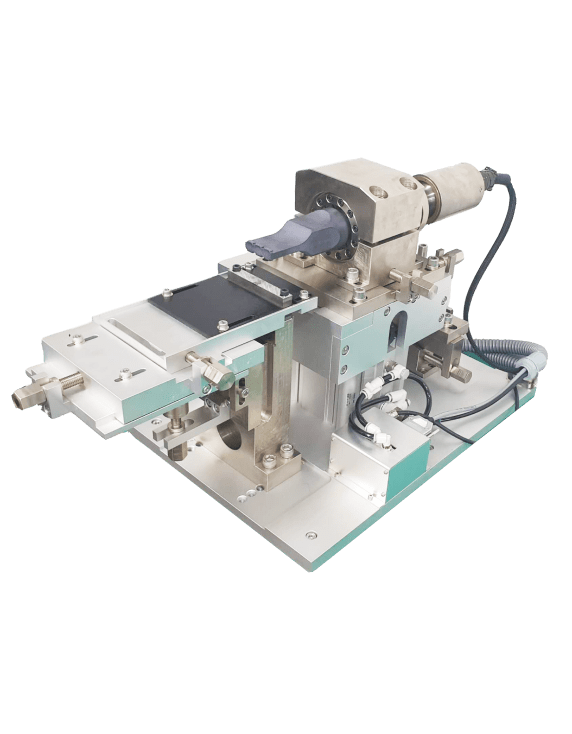

Ultrasonic Metal Spot Welder

ORCA-20

Ultrasonic Metal Tube Sealer is a portable heavy duty 20Khz

ultrasonic welder tooled to seal and cut off charge tubes…

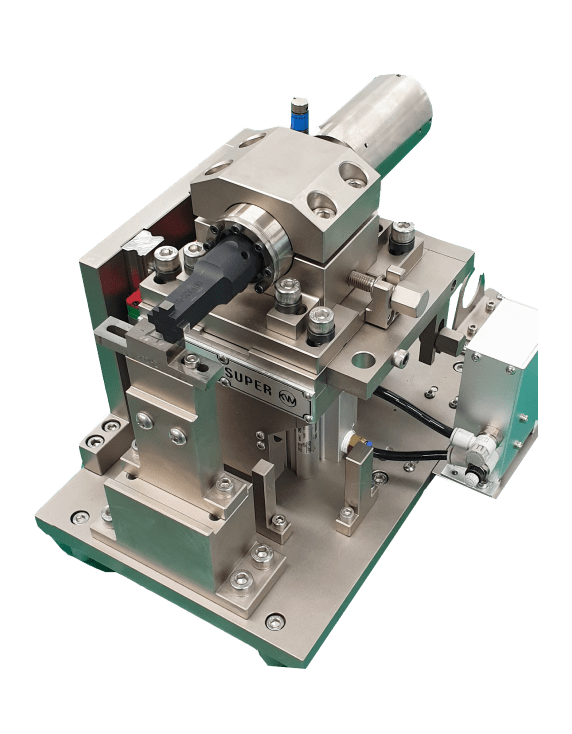

Ultrasonic Metal Spot Welder

ORCA-40

Lithium-ion batteries are considered

the best choice in the production field.

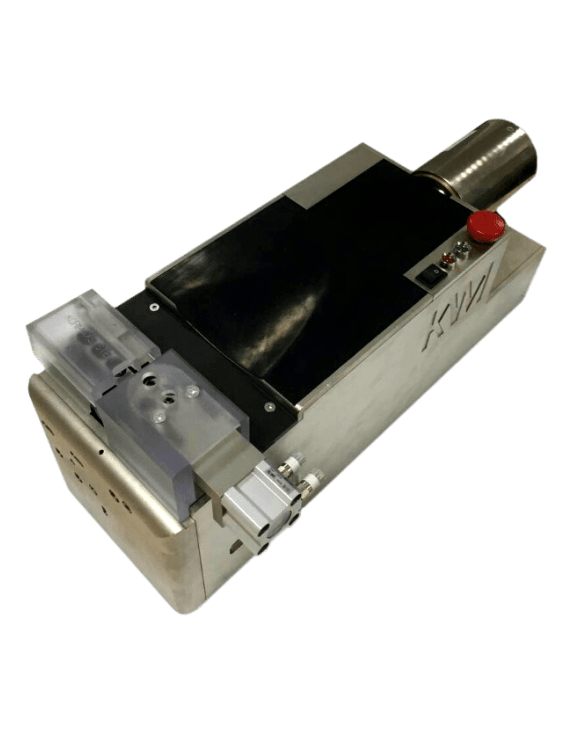

Ultrasonic Copper Tube Sealing Welder

ORCA-SPLICER

This equipment is used in the manufacturing process

of refrigerators and air conditioners.

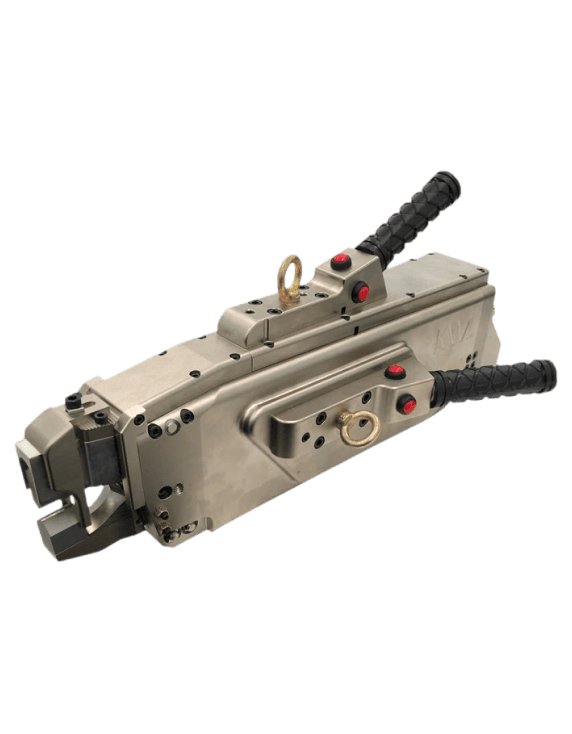

Ultrasonic Metal Wire Splicing Welder

ORCA-SEALER

Ultrasonic welding is being used in automotive electronics

manufacturing to replace traditional methods.

Years Experience

The-HS

Years Experience

The-HS

The Global Leader in Ultrasonic Metal Welding

The-HS: Ultrasonic metal welding machine with a new concept that uses new technologies.

The-HS is a leading provider of ultrasonic metal welding equipment in the world. We work with KORMAX SYSTEM, a world-class ultrasonic welding machine manufacturer, to offer our customers the best possible technology and reliability.

Explore the range of offerings from The-HS

Products

Ultrasonic Metal Spot Welder

ORCA-20

Ultrasonic Metal Spot Welder

ORCA-40

Ultrasonic Copper Tube Sealing Welder

ORCA-SEALER

Ultrasonic Metal Wire Splicing Welder

ORCA-SPLICER

principle

Ultrasonic Welding

Compatibility of Ultrasonic Welding

Check out which materials are suitable for ultrasonic welding.

Piezoelectirc Effect

Piezoelectricity is the conversion of mechanical stress into electrical charge.

Process Principle of Ultrasonic Welding

Take advantage of the effect of reconnecting separated surface layer boundaries.

Components of an Ultrasonic Metal Welder

It consists of a tools (horn & anvil), booster, converter, controller, and mechanism.

The applications of ultrasonic welding machines

Application field

HAVC

(Refrigeration and Air-Conditioning, Cooling and Freeze Devices Industry)

“ORCA-SELAER” be used metal tube to seal and cut off charge in various industrial sectors for the widest range of applications; for instance, it is used in the field of thermostat technology for seal welding capillary tubes or for sealing copper tubes in the production of solar collectors in the field of solar engineering, for example

Wire-Harness, Automobile

“ORCA-SPLICER” is the future-oriented method for wire and terminal applications. Among other things the process is used for joining multiple wires with each other as well as for joining wires with grounding terminals or high-current contacts.

Secondary Battery, Terminal, Socket, Spot Welding

“ORCA-20 & 40” Ultrasonic Metal Welder has the most rapid progress of industrialization industry metal welding applications, especially secondary batteries, lithium-ion battery in a production sector is considered as the best option. Automotive industry, as well as areas for welding the metal material surface and the surface of the defined area, in the electronic component manufacturing, and excellent performance

Explore the benefits of ultrasonic welding with insights from The-HS

Advantages of Ultrasonic Welding Machine

Highest Reliability

Ultrasonic welding can be monitored through time, energy, power and height limits, assuring excellent and comprehensive process controls.

Cost Saving

Requiring less than 1/30 of the energy of resistance welding, and elimination of consumables such as solder, flux, crimp connectors and braze materials make ultrasonic welding the most cost effective and environmentally safe process available for welding. Replacement tooling and maintenance services can be offered from any of our sales offices throughout Korea, Mainland China and Hongkong. We provide tooling for our own machines as well as those from major manufacturers like Stapla, Schunk and AmTech at lowest costs.

Longest Tool Life

We offer economic and easy tooling replacement. Ultrasonic horns are precision machined from high quality tool steel, providing long life, ease of setup and weld accuracy.

Maximum Productivity

Typical weld cycles are within fractions of a second, and thus the maximum industrial productivity is achieved.

Ease of use

our installations are designed and built to ensure simple operation and operator safety.

Automation potential

Minimal maintenance and orientation flexibility make KM-4070 ultrasonic systems the best choice for automatic assembly.

Insulation dispersal

In most cases, the high frequency scrubbing action of the ultrasonic process eliminates the need to strip insulation from magnet wire or to preclean parts.

Environmentally Friendly

No connectors, glue, or solder is needed; no sparks, fumes or arcs are generated during the whole process; lowest noise is produced due to the ergonomic design. All these contribute to the minimization of negative environmental impacts.